Turret Punch or to Laser. That is but one of the many questions you may find yourself asking when seeking an industrial manufacturer to partner with.

The best option for you depends on two things: volume and tooling.

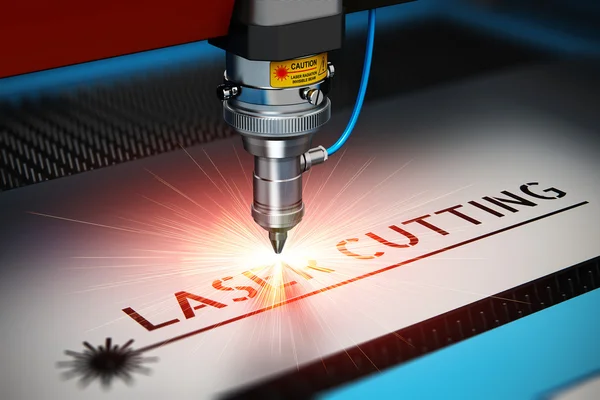

When Is Lasering the Best Option?

When comparing the two options from a financial standpoint; the laser is the more cost-efficient option—even though punching is generally faster. If your industrial product doesn’t have intricate hole placements and form features or has a low volume order capacity; then you may want to consider using a laser.

When Is Turret Punching the Best Option?

If you have a high volume order. A product that has a lot of holes within close proximity or requires formed features—extrusions, lances, c-sinks, etc.; then you may want to consider the punch option. Not only is this faster, but some lasers have difficulties making clean-cut holes that set tightly together. It’s also generally easier and much faster to punch special steels such as aluminum, galvanized and stainless, but this may depend on the capabilities of your manufacturer’s lasers.

While figuring out a budget for your industrial project, keep in mind that punch tooling—based on a thin turret machine—can range anywhere from $300 to $2500. These prices are apt to change depending on the type of tooling and turret. Keep in mind, all tooling comes with an “expiration date,” so this is something you should work out with your industrial manufacturer. Lastly, if your product is made of a thicker gauge, check that your industrial manufacturer’s punch is compatible with thicker steel.

Look into your manufacturer’s capabilities

Much like fingerprints and snowflakes, no two manufacturers will offer the same thing. Some might have high-tech lasers while others might have a turret-punch with laser capabilities. So, be sure to discuss all options with your manufacturer.

Contact us today to learn what we have to offer or read more of our blogs.

Source: https://www.huimfg.com/

Read more blogs